The Ins & Outs of Large OTR Tire Service Trucks in the Mining Industry

03.24.25

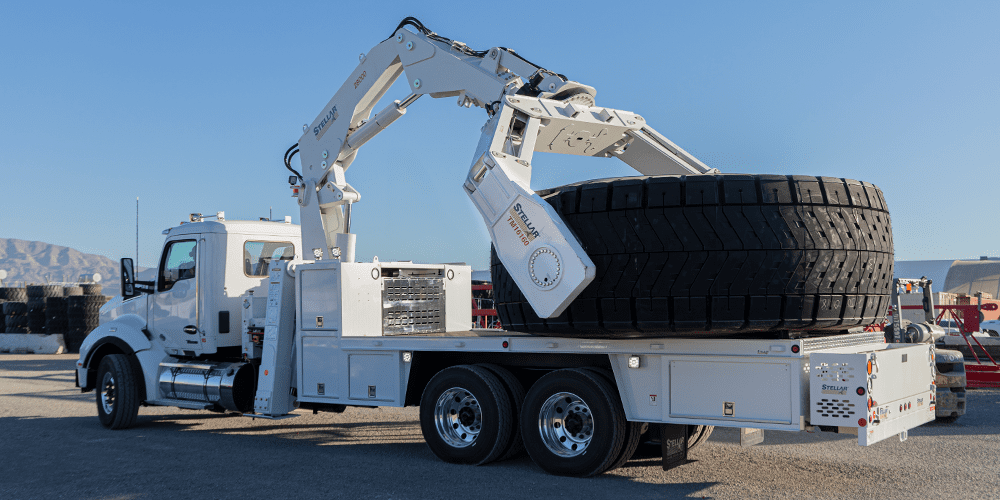

In the mining industry, efficient operation and rapid response to equipment breakdowns are vital for maintaining productivity and profitability. Large off-the-road (OTR) tire service trucks play a critical role in this context, acting as mobile tire repair shops that can navigate mining operations. Specifically designed to handle the unique demands associated with large, heavy tires — like the 59/80 R63 which can weigh up to 18,500 lbs and have a width of 154 inches. These specialized trucks are essential for servicing the enormous tires integral to the operation of heavy mining equipment, such as haul trucks, loaders and support equipment.

The mining sector relies heavily on the continuous operation of its equipment, and tire failures can lead to significant downtime. For example, in surface mining operations, haul trucks are often the backbone of material transportation, and each hour spent repairing a tire translates to lost productivity and revenue. Large OTR tire service trucks enable tire service professionals to address these issues onsite, ensuring that critical machines can resume operations swiftly.

Tire Service Technicians: Ensuring Operational Continuity

Tire service professionals play a crucial role in maintaining the functionality of mining operations, utilizing large OTR tire service trucks to manage the tire program, ensuring a long lifecycle of the tires. Given the substantial impact of tire failures on productivity and the significant financial stakes in the mining industry, where every hour of downtime can lead to major losses, these technicians are essential for minimizing and avoiding operational delays.

With the ability to maintain tires directly onsite with large OTR tire service trucks, these technicians not only perform repairs, but also inspect and do routine maintenance, such as scheduled tire rotations, allowing heavy equipment like haul trucks and loaders to maximize uptime. This helps maintain the continuous operation of mining equipment and also mitigates the financial impact of operational disruptions in a sector characterized by high costs and significant economic value.

The Role of Tire Manipulators

Tire manipulators are sophisticated tools used in conjunction with large OTR tire service trucks to facilitate the efficient handling and replacement of large OTR tires. Tire manipulators act as a mechanical hand for the tire technician, allowing them to safely lift, maneuver and install tires. The tire manipulator allows the tire technician to work without risking injury to themself or the tire and without damaging the equipment.

In addition to improving safety, tire manipulators increase efficiency in tire servicing. In high-stakes environments such as mining, where every minute counts, these tools allow for quicker tire replacements and repairs. This capability is vital for minimizing operational delays and maximizing equipment uptime.

Importance of Tire Manipulators in the Mining Industry

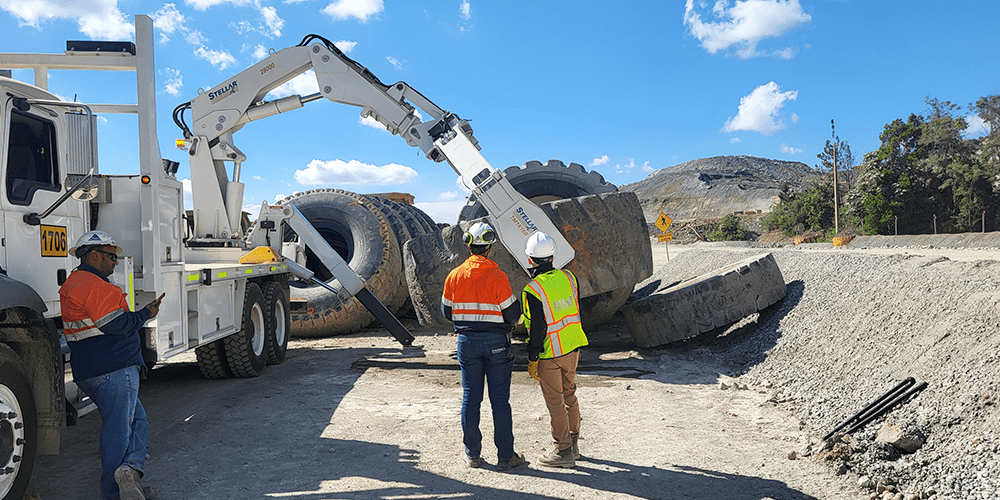

The mining industry faces numerous challenges, including the need to manage costs, maintain equipment availability and operate within the constraints of harsh environmental conditions. Tire manipulators play a crucial role in meeting these challenges by ensuring that equipment can be serviced quickly and effectively.

For instance, in an open-pit mining operation, the distance between equipment can be considerable, making it essential to have a truck that can quickly move between machines that may have broken down or are being serviced. By having large OTR tire service trucks equipped with tire manipulators available to respond quickly, mining companies can avoid lengthy downtime and keep production running smoothly.

Key Features to Look for in Large OTR Tire Service Trucks

To ensure optimal performance and reliability, several key features should be considered when evaluating large OTR tire service trucks:

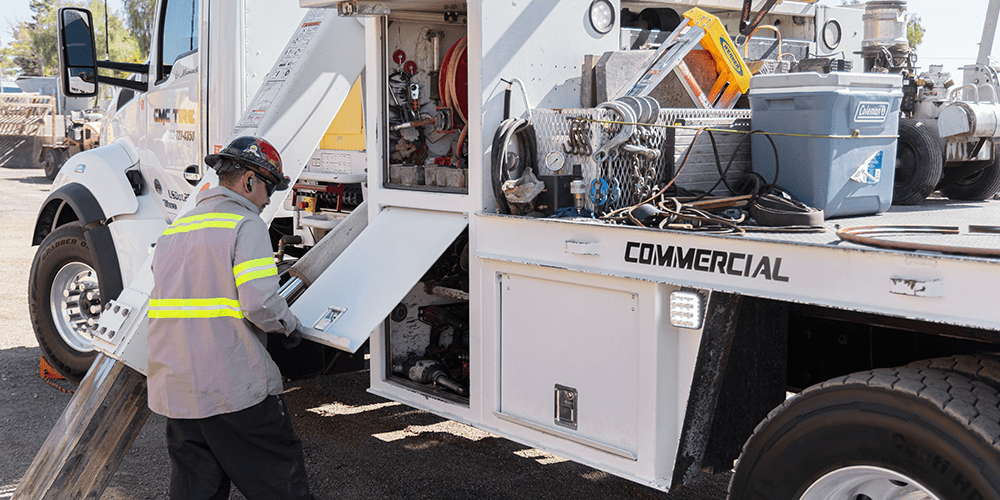

- Integrated Air Compressors: A quality large OTR tire service truck should come with an onboard air compressor that provides the necessary cubic feet per minute (cfm) and pressure (psi) for quick and efficient tire inflation onsite, streamlining the tire servicing process. The compressor is typically a hydraulically driven, four-cylinder two-stage piston compressor to allow for heavy-duty cycles needed in the mining industry. Additionally, these compressors enable technicians to service equipment in other ways, not just airing up tires, such as powering air tools and conducting maintenance tasks that require compressed air, further enhancing the versatility and efficiency of the service truck.

- Stability Features: Stability of the truck is crucial when servicing tires with the tire manipulator. Features like wide-stance stabilizers contribute to safer operations on uneven terrain, reducing the risk of accidents during tire changes. Ideally, look for an A-frame stabilizer design. This feature combines the diversity of out-and-down style stabilizers with a wide stance to adapt to the location and environmental factors, providing maximum stability whether it is mounted on a single- or tandem-axle chassis.

- Storage: The body should be able to store all the necessary tools and parts needed. Look for design elements that facilitate easy access to tools and equipment, such as slide-up-and-in doors and ample, easy-to-access toolbox systems and storage space. Efficient organization within the truck can speed up tire servicing operations.

- Lighting for Low Light Operations: Consider trucks with plenty of LED floodlights to provide visibility during nighttime operations, ensuring that technicians can perform tire changes effectively in low-light conditions. Floodlights allow the technician to position them where needed while skirt-mounted LED lights are set up on the working side for additional light.

Enhancing Performance: Essential Features of Tire Manipulators

When evaluating tire manipulators for use in demanding mining environments, several key features should be prioritized to ensure optimal performance and safety:

- Control Systems: Opt for large OTR tire service trucks equipped with both wireless radio remote control and backup manual control options. The remote control should allow for multiple functions to run at once and for the speed of those functions to be controlled by the technician. This provides precise control of the tire for the technician, allows them to be in a safe area and gives visibility during tire servicing.

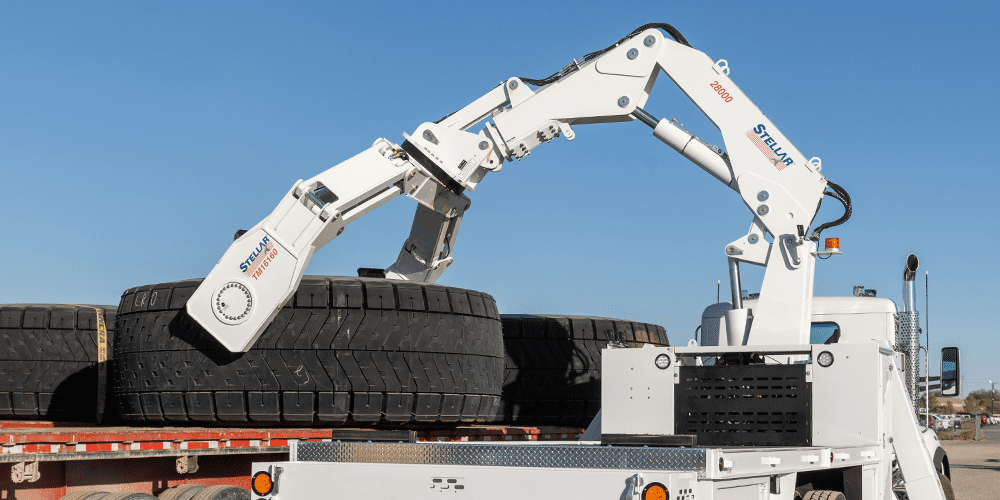

- Parallelogram Design: This design is critical for achieving consistent clamping pressure and providing a secure grip on large tires. By eliminating the need for additional pad extensions, it ensures safe handling during tire servicing, which is crucial for maintaining the integrity of the tire throughout the process.

- Continuous Rotation Pads: Many high-quality tire manipulators are equipped with continuous rotating pads. This feature enhances flexibility when positioning tires, allowing operators to achieve precise alignment during installation, which is important for ensuring that tires are mounted correctly.

- Adjustable Clamping Distances: Tire manipulators should offer various opening and closing clamping distances to accommodate different tire sizes. This versatility ensures that the manipulators can meet the diverse needs of mining operations, effectively handling a wide range of tire dimensions without compromising performance.

- Hexagon Boom Design: Quality tire manipulators should be designed to handle the rigors of the mining industry. Hexagonal boom design increases the strength of the boom while reducing the amount of flex it can sustain when under a heavy load.

Key Assets in Mining Efficiency

As the mining industry continues to face pressures to enhance productivity and efficiency, the importance of large OTR tire service trucks and tire manipulators cannot be overstated. These advanced tools improve operational efficiency and significantly enhance worker safety and equipment reliability.

Moreover, as the mining industry evolves and machinery becomes more sophisticated, the demand for larger and more complex tires continues to grow. Large OTR tire service trucks equipped with advanced tire manipulators will be vital in meeting these evolving needs, ensuring that mining operations can keep pace with technological advancements while minimizing downtime.

By leveraging the capabilities of large OTR tire service trucks and tire manipulators, mining companies can ensure that their operations remain productive and profitable, even amidst the challenges posed by demanding working conditions and the requirements of mining machinery. As the sector advances, investing and utilizing these essential tools will be critical to maintaining a competitive edge in the ever-evolving landscape of the mining industry.

For more information on Stellar’s OTR tire trucks and manipulators, contact us or find an international distributor.

This article was originally created for Global Mining Review.

For related content, go to:

- Stellar Tire Trucks & Manipulators Brochure

- OTR Tire Capacity Chart

- Large OTR Tool Package

- Video & More: A Stellar MINExpo Experience

- Stellar and Maxilift Australia Succeed Through Partnership

- Stellar Tire Service Trucks: Purcell Tire’s Secret Weapon

- Hart Bros Count on Stellar OTR Tire Service Trucks

- Stellar Partners with Titan International and Tire Industry Association for Hands-On Training

- Enhancing Mining Operations with Specialized Mechanic Trucks

- Stellar Debuts New Aluminum Option for TMAX 3T Mechanic Truck (Tandem Axle) at MINExpo 2024